Abdesslem Chaouch.

Mechatronic Engineer

Ottawa,Ca

Background.

How I Add Value.

Creating reliable, safe systems that unite mechanics, electronics, and intelligent control.

Optimizing processes to minimize scrap and maximize efficiency.

By targeting the key Pareto drivers, developing structured action plans, analyzing customer technical specifications, and leading stop-scrap projects to reduce waste and stabilize production.

Quality & Safety Frameworks

Keep learning.

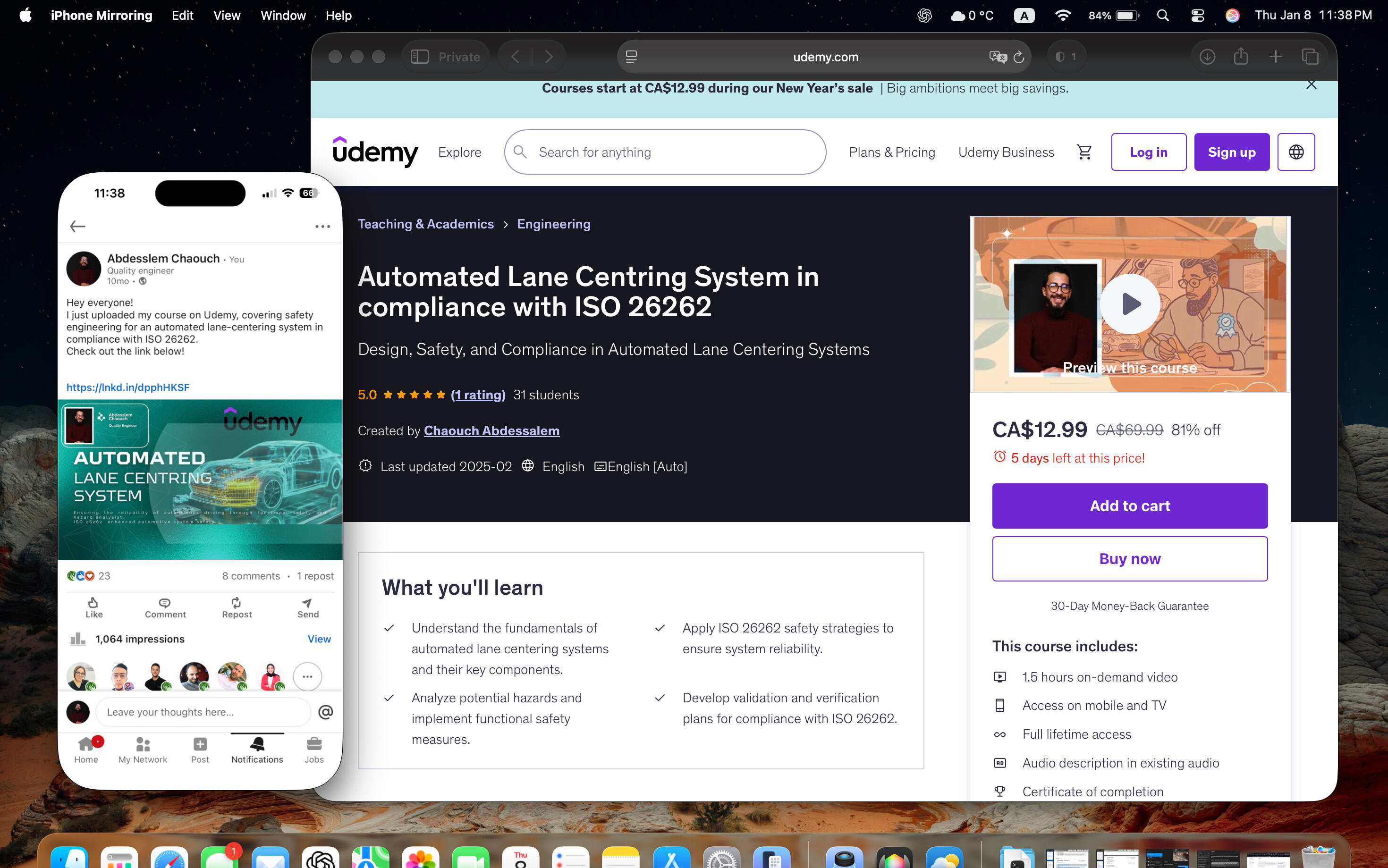

In my Udemy course on ISO 26262 functional safety, I guide you through the integrated application of STPA, FMEA, and HARA. Master the process of defining critical safety goals and ASILs for complex systems like Automated Lane Centering.

👉 Udemy course Link

Let’s Get In Touch.

or reach out manually to

Email 📧 : [email protected]

Linkedin 🏢 : abdessalem chaouch

-1.png?width=1584&height=960&name=Axify%20blogue%20header%20(6)-1.png)